Structural integrity experts play a crucial role in ensuring vehicle safety and durability during auto frame repair and fender repair. They collaborate with welding teams, utilizing advanced techniques and tools to evaluate weld integrity, stress points, alignment, and material properties. This partnership guarantees repaired vehicles are not only aesthetically pleasing but also perform optimally and provide enhanced passenger security. Their continuous monitoring and rigorous inspections identify potential flaws, ensuring every weld meets required specifications, thereby upholding safety, quality, and the longevity of vehicles in automotive collision repair and tire services.

Structural integrity experts play a vital role in ensuring the safety and durability of welded structures. They collaborate closely with welding teams throughout every stage, from initial planning to final execution. By combining their specialized knowledge with practical experience, these experts guide teams in selecting appropriate welding techniques, materials, and quality control measures. Through continuous monitoring and rigorous testing, they maintain the highest standards, ensuring the structural integrity of each weld.

- Understanding Structural Integrity Experts' Role in Welding

- Collaboration Process: From Planning to Execution

- Ensuring Safety and Quality Through Continuous Monitoring

Understanding Structural Integrity Experts' Role in Welding

Structural integrity experts play a pivotal role in ensuring the safety and durability of vehicles, particularly during auto frame repair or fender repair processes. Their expertise lies in evaluating and maintaining the structural soundness of vehicles, which is crucial for their overall performance and passenger security. These professionals work hand-in-hand with welding teams to guarantee that every joint and component meets the required standards.

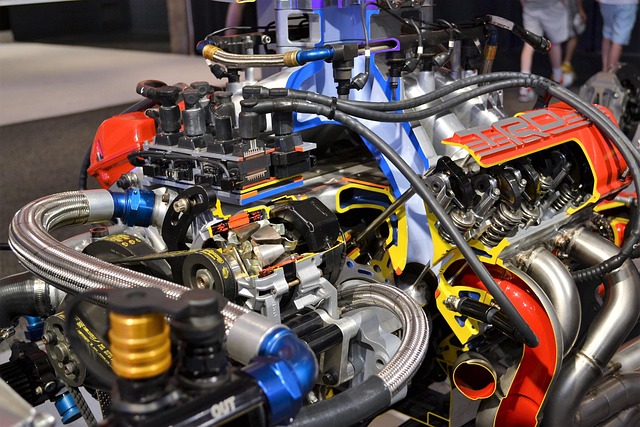

By employing advanced techniques and tools, they assess the integrity of welds, identifying any potential weaknesses or defects. This meticulous process involves analyzing stress points, checking alignment, and verifying material properties. Their involvement in vehicle restoration projects ensures that repaired vehicles not only look good but also function optimally, enhancing safety for every journey.

Collaboration Process: From Planning to Execution

The collaboration process between structural integrity experts and welding teams is a seamless blend of technical knowledge, meticulous planning, and precise execution. It begins with detailed discussions to understand the project’s unique challenges and requirements. Structural integrity experts, well-versed in material science and structural analysis, work closely with the team to develop tailored solutions that meet safety standards and performance criteria. This collaborative phase involves defining design specifications, selecting appropriate welding techniques, and creating a comprehensive plan to ensure every aspect is considered.

During execution, these experts oversee the process, providing real-time guidance and quality control. They monitor welds for accuracy, ensuring they align with the initial design intent. By integrating their expertise seamlessly into the workflow of the welding team, structural integrity experts help deliver projects that not only meet but exceed expectations. This partnership is pivotal in industries like automotive body shops, where precision and structural soundness are paramount, especially in vehicle repair services.

Ensuring Safety and Quality Through Continuous Monitoring

Structural integrity experts play a pivotal role in ensuring safety and quality during welding processes, working closely with teams to maintain meticulous standards. Their expertise lies in continuous monitoring, where they employ advanced techniques and tools to assess weld integrity throughout every stage of production. By implementing rigorous inspections, these professionals can identify potential flaws or inconsistencies that might go unnoticed by untrained eyes.

This ongoing surveillance is crucial for preventing issues in automotive collision repair and tire services, which often rely on robust welding for structural integrity. The experts’ keen eye for detail guarantees that each weld meets the required specifications, ensuring the overall reliability and longevity of vehicles undergoing repairs or modifications. Their presence acts as a safeguard against subpar work, ultimately enhancing the quality of auto painting and other specialized services within the industry.

Structural integrity experts play a vital role in ensuring the safety and quality of welding projects through close collaboration with skilled teams. By implementing comprehensive planning, meticulous monitoring, and continuous feedback, these experts navigate complex structural demands, fostering an environment where precision and compliance thrive. Their expertise enhances the overall efficiency of welding operations, delivering robust and reliable structures.